Generators are essential for keeping homes powered during outages, yet many homeowners overlook the importance of regular maintenance. This blog post will cover key strategies for maximizing efficiency, including scheduling routine inspections, implementing effective cleaning procedures, and monitoring oil and filters. By following these generator maintenance strategies, readers will enhance reliability and extend the lifespan of their equipment. Addressing common pain points, such as unexpected failures, this content will provide valuable knowledge to ensure optimal performance and superior customer service in electrical diagnostics.

Regular generator maintenance is essential for homeowners to avoid costly breakdowns through preventive care. By ensuring that backup systems are in optimal condition through electrical diagnostics, customers can significantly reduce the risk of emergency failures. Proper maintenance not only extends the generator’s lifespan but also enhances reliability, allowing technicians to address potential issues before they escalate.

Preventive care is vital for avoiding costly breakdowns in standby power systems. Regular generator maintenance, including checks on the exhaust system and other critical components, helps identify potential issues early. Homeowners who engage with reliable generator maintenance service providers can ensure their systems remain efficient and ready for use, ultimately protecting their investment and ensuring peace of mind.

Extending the lifespan of an electric generator, such as a Generac, requires regular maintenance and attention to detail. By scheduling routine inspections with an expert technician, homeowners can identify and resolve minor issues before they lead to significant problems, especially during a power outage. This proactive approach not only enhances the generator’s reliability but also helps maintain the reputation of the system as a dependable backup power source.

Setting up a maintenance checklist for generator inspections is crucial to prevent failures and minimize downtime. Assigning responsibilities to qualified technicians ensures that all components, including coolant levels, are regularly checked. This proactive approach not only enhances the longevity of the generator but also helps maintain warranty coverage, safeguarding the investment in reliable backup power.

Creating a maintenance checklist for inspections is a critical step in ensuring the reliability of a standby generator. This checklist should include essential tasks such as testing the transfer switch, checking coolant levels, and scheduling load bank tests to assess the generator’s performance under load. By partnering with a reputable generator service company and having a qualified electrician conduct these inspections, homeowners can proactively address potential issues, ensuring their generator remains in optimal condition and ready for use when needed.

Assigning responsibilities to qualified technicians is crucial for effective generator maintenance. These professionals should be well-versed in the guidelines set by the National Fire Protection Association, ensuring that all safety protocols are followed during inspections. Regular checks on oil levels and diesel fuel quality, along with the implementation of remote monitoring systems, can help identify issues before they escalate, providing homeowners with peace of mind and reliable emergency generator service when needed.

Effective cleaning procedures are essential for maintaining generator efficiency. Removing accumulated dust helps prevent overheating, ensuring the generator operates smoothly. Additionally, cleaning fuel tanks is crucial to avoid contamination, which can lead to costly emergency generator repairs. These practices are vital for all brands, including Cummins, and contribute to the longevity of industrial generator repair services.

Removing accumulated dust from generators is crucial for maintaining uptime and preventing overheating. Dust buildup can obstruct airflow, leading to inefficient operation and potential damage to components such as switchgear. For facilities in New York City that rely on natural gas generators for manufacturing, regular cleaning is essential to ensure optimal performance and reliability during peak demand periods.

Cleaning fuel tanks is a critical maintenance task that helps avoid contamination in generators. Contaminated fuel can lead to engine performance issues and costly repairs, making regular cleaning essential for optimal operation. By scheduling annual cleanings and using qualified technicians, homeowners can ensure their generators run efficiently and reliably, safeguarding their investment in backup power systems.

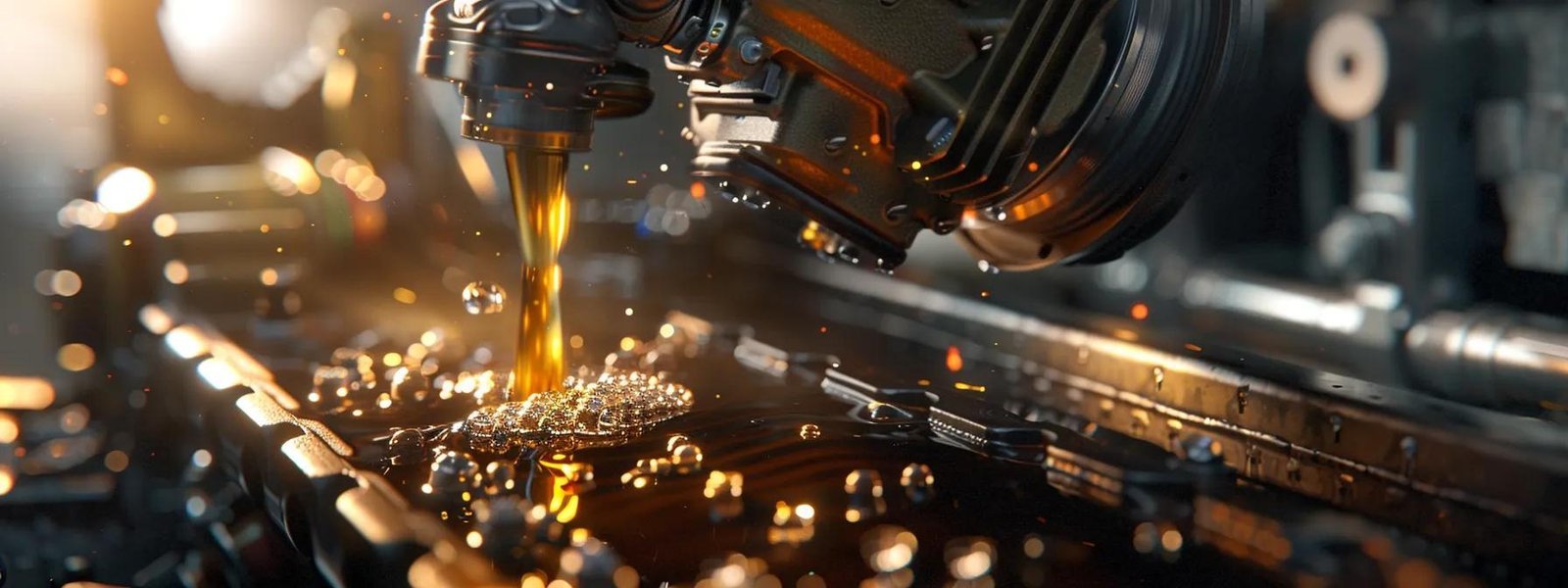

Regularly checking oil quality and levels is essential for maintaining generator efficiency. Homeowners should also replace air and fuel filters according to the recommended schedule. These practices ensure optimal performance and reliability, preventing potential issues that could arise from neglect. By adhering to these maintenance strategies, homeowners can maximize the lifespan and effectiveness of their generators.

Checking the oil quality and level frequently is a fundamental aspect of generator maintenance that directly impacts performance and efficiency. Homeowners should inspect the oil at regular intervals, looking for signs of contamination or degradation, as dirty oil can lead to engine wear and reduced reliability. By maintaining proper oil levels and quality, homeowners can ensure their generators operate smoothly, minimizing the risk of unexpected failures during critical times.

Replacing air and fuel filters according to the manufacturer’s schedule is crucial for maintaining generator efficiency. Clean filters ensure that the generator receives an uninterrupted supply of clean air and fuel, which directly impacts its performance and longevity. Homeowners should prioritize this maintenance task to prevent issues such as reduced power output and increased fuel consumption, ultimately safeguarding their investment in backup power systems.

Conducting regular battery load tests is essential for ensuring generator reliability. Homeowners should monitor battery performance closely and install fresh batteries when performance declines. These practices not only enhance the efficiency of the generator but also prevent unexpected failures during power outages. The following sections will provide detailed insights into how to effectively test and replace generator batteries.

Conducting regular battery load tests is a critical aspect of generator maintenance that ensures reliability during power outages. By testing the battery’s performance, homeowners can identify any decline in capacity and replace it before it fails. This proactive approach not only enhances the efficiency of the generator but also provides peace of mind, knowing that the backup power system is ready to perform when needed.

Installing fresh batteries when performance declines is crucial for maintaining the reliability of a generator. Homeowners should regularly monitor battery performance, as a decline can indicate that the battery is nearing the end of its life. By proactively replacing batteries, homeowners can ensure their generator remains ready to provide backup power during outages, ultimately enhancing the efficiency and dependability of their home’s electrical system.

Stocking essential spare parts is crucial for immediate repairs, ensuring that generators remain operational during outages. Additionally, preparing emergency protocols for power outages helps homeowners respond effectively when the need arises. These strategies not only enhance generator efficiency but also provide peace of mind, knowing that backup systems are ready to perform when required.

Stocking essential spare parts for generators is a proactive strategy that ensures immediate repairs can be made during power outages. Homeowners should consider keeping items such as oil filters, air filters, and batteries on hand, as these components are often the first to require replacement. By having these spares readily available, homeowners can minimize downtime and maintain the efficiency of their backup power systems, ensuring they are always prepared for unexpected outages.

Preparing emergency protocols for power outages is essential for homeowners relying on generators. Establishing a clear plan that outlines steps to take during an outage can significantly reduce stress and ensure a swift response. This includes knowing how to safely operate the generator, having contact information for service providers, and keeping essential supplies readily available, which ultimately enhances the efficiency and reliability of the backup power system.

Maximizing efficiency through regular generator maintenance is crucial for homeowners to ensure reliable backup power during outages. Implementing preventive care, such as routine inspections and timely oil changes, significantly reduces the risk of costly breakdowns. Keeping essential spare parts on hand and preparing emergency protocols further enhances readiness and peace of mind. By prioritizing these maintenance strategies, homeowners can protect their investment and ensure their generators operate at peak performance when needed most.