Is your generator ready for the next power outage? Annual generator maintenance is essential to ensure your system operates smoothly and reliably when you need it most. This article will guide you through the key components of a maintenance checklist, step-by-step procedures, and common issues to watch out for during inspections. By reading this content, homeowners will gain insights into the benefits of timely maintenance and learn when to consider professional services. Don’t let unexpected failures disrupt your comfort—understanding these maintenance steps can help you stay prepared.

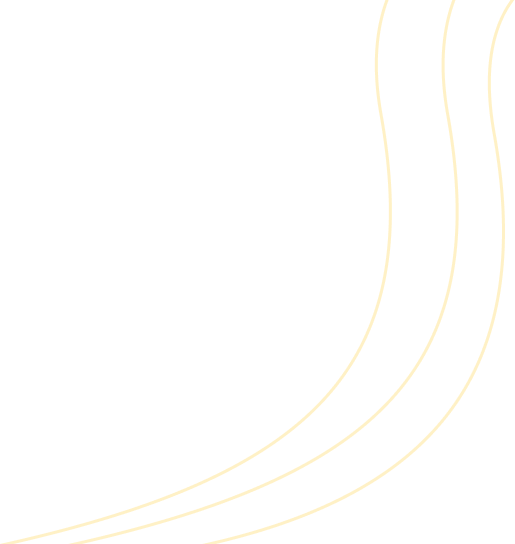

Annual generator maintenance is essential for ensuring optimal performance and longevity of both diesel generators and electric generators. Regular maintenance tasks, such as inspecting the bearing and checking fluid levels, can prevent costly failures and enhance reliability during outages.

Neglecting these maintenance tasks can lead to decreased efficiency and potential breakdowns when the generator is needed most. A well-maintained Cummins generator, for example, will operate more smoothly and provide consistent power, minimizing the risk of unexpected issues.

Performing annual maintenance helps identify wear and tear before it becomes a serious problem. Homeowners can enjoy peace of mind knowing their generators are ready to perform when required, ensuring their home remains powered during emergencies:

Essential steps for annual generator maintenance include inspecting and replacing oil and fuel filters, checking fuel systems and lines, and evaluating battery condition and connections. Additionally, examining the cooling system and testing the exhaust system ensures that generators perform optimally. These tasks enhance reliability during emergencies and improve concentration on essential power needs, keeping homes prepared with effective transfer switches and block heaters.

Inspecting and replacing oil and filters is a crucial aspect of annual generator maintenance, as it ensures the generator operates efficiently and effectively during power outages. Regular oil changes help to identify potential leaks and prevent sludge buildup, which can lead to operational issues, while new filters optimize fuel flow and protect the engine’s integrity. For homeowners relying on standby power, thorough maintenance provides peace of mind, assuring that their generator is ready for emergencies when needed most, reinforcing the importance of proper ATS maintenance.

Checking fuel systems and lines is a vital element of annual generator maintenance, as it ensures reliable performance during a power outage. Homeowners should inspect the crankcase and fuel pump for leaks and ensure that the fuel lines are clear of debris that could obstruct flow. Additionally, checking coolant levels helps maintain optimal operating temperatures, preventing overheating and costly repairs:

Evaluating the condition of the battery and its connections is a critical step in the annual generator maintenance checklist. This inspection should focus on checking for corrosion on the terminals and ensuring tight connections to avoid power loss. Homeowners should also assess the battery charger to confirm it’s functioning properly, as a reliable battery plays a vital role in the overall performance of a commercial generator during emergencies.

Examining the cooling system is a fundamental part of the annual inspection for any backup generator. This process ensures that the owner maintains optimal operating temperatures, preventing overheating that can lead to serious damage. An effective cooling system relies on various components, including the oil filter and coolant tank, to function properly; therefore, it is imperative for homeowners to regularly check for leaks, coolant levels, and any signs of wear.

Testing the exhaust system is a critical step in the generator maintenance checklist that ensures safety and optimal performance. A properly functioning muffler minimizes noise and keeps exhaust emissions at safe levels, which is essential for compliance with regulations regarding heavy equipment. Certified technicians should inspect the exhaust system, looking for cracks or blockages that could hinder both intake and exhaust flow, thereby preventing potential issues during operation.

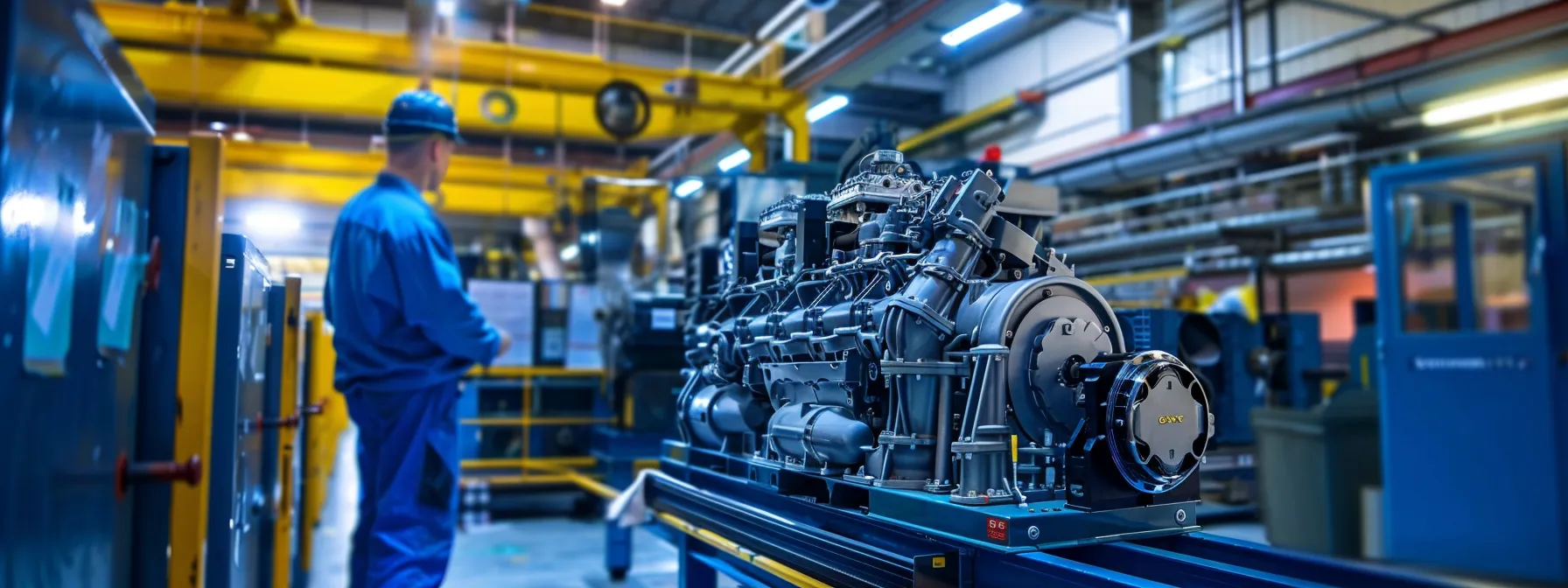

Preparing the generator for maintenance starts with conducting safety checks to ensure the machine is safe to service. Following these safety protocols, homeowners can perform routine functional tests to monitor overall performance. Documenting maintenance findings is crucial for tracking issues, while scheduling future maintenance ensures consistent care. Attention to these tasks is essential in adhering to a generator maintenance checklist, including checking heat levels and antifreeze conditions.

Preparing a standby generator for maintenance is vital for extending its lifespan and ensuring reliability during an emergency. Homeowners should begin by consulting the generator’s manual, which provides specific guidelines on safety precautions. Before any work begins, a qualified technician should check for wear and assess the air filter, ensuring it is clean and functioning properly to maintain optimal performance. This proactive approach not only enhances the generator’s efficiency but also assures that it is ready to provide emergency service when needed most.

Before servicing a generator, conducting thorough safety checks is critical to ensure the power supply remains stable and uninterrupted. Homeowners should verify that the circuit breaker is in the off position and inspect the exhaust system for any signs of wear or damage. Additionally, it is essential to check the fuel tank and associated pipes for leaks or blockages that could hinder performance. Taking these steps helps prevent accidents and ensures the generator operates efficiently during emergencies.

Performing routine functional tests is a vital part of generator maintenance service, ensuring that the unit operates effectively during power interruptions. This involves checking the oil levels and examining the spark plug for wear, which directly influences energy output and reliability. By connecting the generator to a load bank, homeowners can simulate a power draw to assess its performance under typical conditions, helping to identify any potential issues before they become serious problems:

Documenting maintenance findings is crucial for effective generator upkeep. Homeowners should maintain records of lubricant changes, carbon monoxide levels, and the condition of belts and valves after each servicing. This systematic approach aids in diagnosing potential failures and enhances the overall performance and reliability of the generator during power interruptions.

Scheduling future maintenance for a generator is crucial for ensuring consistent performance and reliability. Homeowners should set reminders for key checks, such as voltage levels and radiator functionality, as part of their preventative maintenance routine. This proactive approach can help identify issues early, preventing operational failures during critical times when the generator is needed the most:

During annual maintenance, one common issue that can arise involves the engine fluid levels. Insufficient fluids can significantly impact the generator’s performance, leading to overheating or mechanical failure. Keeping a checklist for fluid inspections ensures that contaminants do not compromise functionality.

Another frequent concern is the condition of electrical components within the generator. Faulty connections can lead to unplanned outages and safety risks. Utilizing electrical diagnostics services can help identify these issues before they escalate, ensuring the generator remains reliable during critical situations.

Finally, wear and tear on the generator’s mechanical parts can be detected during maintenance checks. Components such as belts and filters may need replacement to maintain optimal performance. Regular inspections can prevent accidents, ensuring that the generator operates smoothly when needed most.

Completing annual generator maintenance on schedule is vital for maintaining the current performance levels of the unit. Regular maintenance helps identify issues before they escalate into costly problems, ensuring the generator operates smoothly. Homeowners benefit from a dependable power source during outages when maintenance is prioritized.

Staying current with maintenance can also protect a homeowner’s warranty. Many manufacturers require proof of regular servicing to keep the warranty valid. By adhering to the maintenance schedule, homeowners can avoid potential disputes with manufacturers regarding warranty claims.

Consistent maintenance enhances the lifespan of the generator, helping to ensure long-term reliability. Clean filters, fluid checks, and functional components contribute to efficient operation, reducing the risk of unexpected breakdowns. Homeowners gain peace of mind, knowing their generator will be ready to perform when emergencies arise:

Choosing the right service provider for generator maintenance is essential for optimal performance. Cost considerations for professional services can vary, impacting a homeowner’s decision. It is also important to understand how maintenance affects warranty implications. Each of these topics offers practical insights into making informed decisions, ensuring reliable generator operation year after year.

When selecting a service provider for generator maintenance, homeowners should prioritize companies that have a solid reputation, relevant experience, and professional certifications. Verifying client testimonials and assessing the qualifications of technicians ensures reliable service, which is vital for maintaining generator performance. A knowledgeable provider can offer insights on preventive maintenance specific to each generator model, effectively addressing the homeowner’s needs:

Cost considerations for professional generator maintenance vary widely based on service provider experience, regional market rates, and the specific generator model. Homeowners must assess not only the hourly labor rates but also the inclusiveness of the service package, such as inspections and parts replacements. Investing in qualified professionals can lead to long-term savings by preventing costly breakdowns and ensuring optimal functioning during power outages.

Understanding warranty implications for generator maintenance is crucial for homeowners. Most manufacturers require proof of regular maintenance to keep warranties valid, so skipping services could void coverage. By scheduling annual check-ups with a qualified service provider, homeowners not only ensure their generators remain operational during outages but also protect their investment, avoiding unexpected repair costs and maintaining peace of mind.

Homeowners often face the decision between performing DIY generator maintenance and hiring a professional service. While many routine tasks, such as checking fluid levels and replacing oil filters, can be conducted by a knowledgeable homeowner, complex issues may require expert intervention to ensure safety and efficiency.

Choosing professional generator maintenance ensures access to trained technicians who can identify underlying problems that a homeowner might overlook. These experts possess the experience and equipment necessary to conduct comprehensive inspections, safeguarding the generator’s performance during critical power outages.

Ultimately, the decision should be based on the homeowner’s comfort level with technical tasks and the specific needs of their generator. Regular professional maintenance enhances reliability, prolongs generator life, and minimizes the risk of unexpected failures when power is most needed.

Regular generator maintenance is vital for ensuring reliable operation and preventing costly breakdowns. Key steps include inspecting and replacing oil and filters, checking fuel systems, evaluating battery condition, and examining the cooling and exhaust systems. Implementing these actions not only enhances generator performance but also extends its lifespan, providing peace of mind during power outages. Homeowners should prioritize annual maintenance to safeguard their investment and ensure their generators are always ready to perform in emergencies.